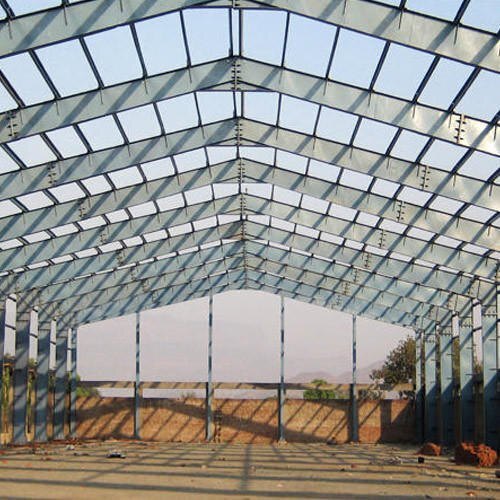

At Mecma Engineers, we undertake the design, fabrication, and erection of complex steel structures that form the backbone of industrial facilities. Our structural works include pipe racks, platforms, walkways, ladders, support beams, sheds, and mezzanines, among others. These structures are fabricated from mild steel, stainless steel, or custom alloys, ensuring strength and reliability even in the most demanding operating conditions.

We follow precise engineering drawings and fabrication standards while offering surface treatments such as galvanizing or epoxy painting for long-term durability. Our on-site erection services are backed by qualified personnel and safety-first practices, ensuring timely and secure installations at project locations.

We manufacture and install a wide variety of industrial storage tanks tailored to hold liquids, gases, and chemicals. Our product range includes vertical tanks, horizontal tanks, cone-bottom tanks, jacketed tanks, and double-walled tanks in stainless steel, mild steel, and other corrosion-resistant alloys.

These tanks are used for storing acids, solvents, water, fuel, and other critical substances, and are built to withstand internal pressure, corrosive environments, and thermal stress. Mecma Engineers also provides tanks with agitators, insulation, heat tracing, and access ladders or platforms as per client requirements. All tanks are tested for leakage, material integrity, and design compliance before dispatch.

Pressure vessels are a core component in many chemical and industrial processes, and Mecma Engineers excels in fabricating them with utmost precision and safety. We produce a range of pressure vessels including reactors, autoclaves, separators, and air receivers, designed to operate under high pressure and temperature conditions.

All our vessels are manufactured in accordance with ASME Section VIII and other international codes. From material selection to radiographic testing and hydrostatic pressure trials, every stage is closely monitored to ensure safe, long-lasting operation. We provide both horizontal and vertical configurations with accessories such as nozzles, manways, and internal coils as per process demands.

We offer robust and efficient heat exchangers designed to transfer heat between two or more fluids in a wide range of chemical and thermal applications. Our specialty lies in manufacturing shell-and-tube heat exchangers, which are widely used for their versatility and efficiency.

The design takes into consideration flow rate, pressure drop, thermal conductivity, and fouling factors. With a deep understanding of thermal engineering, our team ensures that every unit is optimized for energy conservation and long-term reliability. Materials range from stainless steel and carbon steel to exotic alloys like Hastelloy or Inconel depending on the fluid media involved.

Mecma Engineers fabricates high-performance distillation columns used in the separation and purification of liquid mixtures. These columns are an essential part of any chemical, petrochemical, or pharmaceutical plant, and are offered in packed bed and tray-type designs.

We manufacture columns that can handle varying reflux ratios, pressures, and temperature ranges, with provisions for feed points, vapor-liquid separation zones, reboilers, condensers, and sampling ports. Our team ensures proper fluid dynamics and mechanical stability, offering equipment that guarantees purity levels, throughput efficiency, and low maintenance.

We offer a complete range of process equipment designed to meet the complex needs of chemical and pharmaceutical manufacturing units. Our product portfolio includes hydrogenator reactors, GMP/Non-GMP reactors, condensers, autoclaves, scrubbers, agitated vessels, and more.

Each piece of equipment is customized as per client specifications and is manufactured with high-quality materials to withstand harsh processing environments. We integrate features such as heating/cooling jackets, internal agitators, vacuum systems, and automation-ready ports to facilitate efficient operation. Mecma Engineers ensures all equipment complies with regulatory and quality standards, ensuring optimal safety and productivity.

Beyond manufacturing, Mecma Engineers also takes complete responsibility for the on-site installation and commissioning of industrial machinery. Our team ensures precise alignment, vibration control, anchoring, and piping connections during installation to guarantee smooth and efficient machine operation.

Whether it’s a single vessel or an entire process line, we handle layout planning, foundation works, mechanical fittings, utility connections, and trial runs with complete project accountability. Our fabrication team is also available to modify or retrofit existing machinery setups to meet new production demands or standards.

Recognizing the importance of skilled labor in executing industrial projects, Mecma Engineers provides a well-trained and reliable workforce tailored to your project’s needs. We supply experienced welders, fitters, riggers, fabricators, supervisors, and safety personnel for short-term or long-term assignments.

Our manpower team is trained in safety protocols, fabrication standards, and operational best practices, ensuring they are productive from day one. Clients benefit from reduced downtime, enhanced quality, and the flexibility of scaling workforce requirements as projects progress. We prioritize safety, efficiency, and professionalism in every manpower engagement.

Copyright © 2025 Mecma Engineers | Designed by Z Web Solutions